Die handling cranes

Die handling cranes

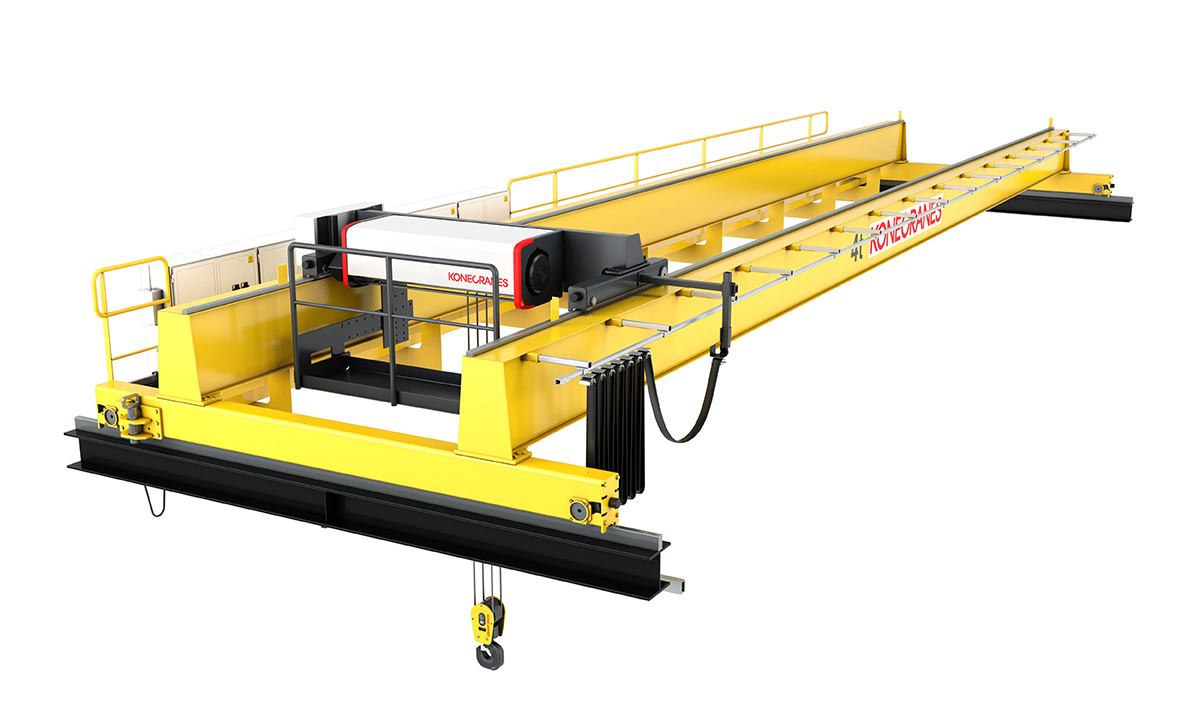

In press shops, dies are typically handled with slings on all four corners or with a special lifting device like a die gripper. Konecranes offers several types of cranes for die handling purposes including CXT®, SMARTON® and UNITON™ cranes.

Making cars and trucks requires efficient production and reliable equipment. Konecranes has cranes with features for safe and easy operation. Crane cycle times are reduced using PLC controlling, position sensoring, radio controls, Sway Control and semi-auto functions.

Die turning and rope angles

When the upper part of a die is turned for service, large rope angles around six to 12 degrees can build up. The angles are related to the rope length and the distance between the hooks.

Cranes can be equipped with a die gripper -- or die lifter. The operator can control the width and length of the gripper using a radio controller. Gripper legs are controlled by the inverter. The needed positioning accuracy of a die gripper crane is usually around +/- 20 mm with the following measures:

- two lasers for bridge position measurement, one for the trolley

- rotating absolute encoder for hoisting

- closed-loop inverter control

- strict mechanical tolerances and accurate movements

Using camera views with radio controller

Handling a die in a warehouse or at a bolster requires high accuracy. Konecranes has developed a tablet that works with the radio controller to show a camera view to the operator. This helps the operator easily position the die gripper to the lifting pin of a die. Cameras can be mounted to the die gripper or the trolley.