The next step in the evolution of design

The next step in the evolution of design

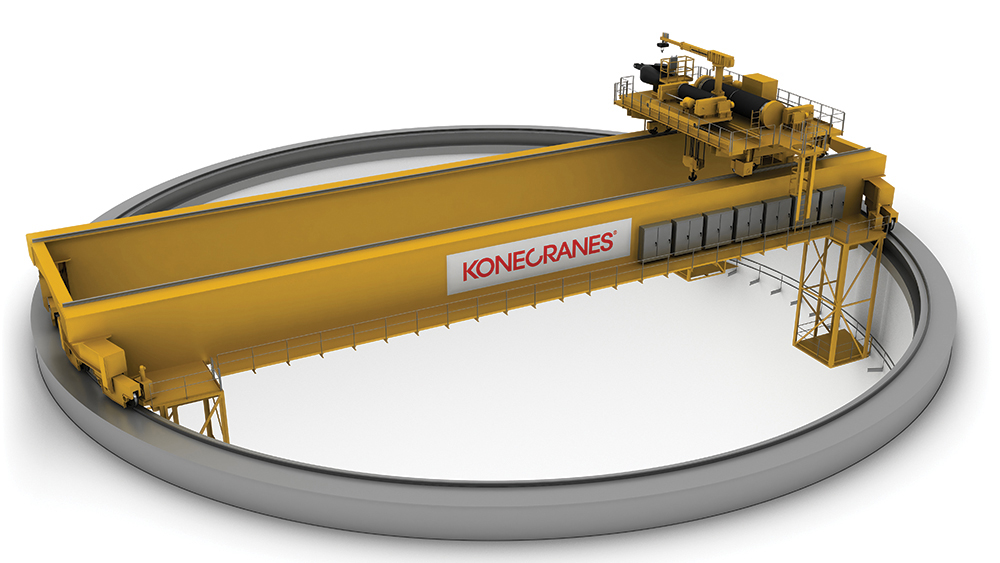

Our latest evolution of polar cranes utilizes a multipurpose design that maximizes operational capability by combining numerous lifting features into a single compact and weight-efficient trolley. The design improves productivity and reliability by providing four primary lifting systems including a main hoist, auxiliary hoist, maintenance jib crane, and containment inspection man lift, all conveniently located on one trolley.

The polar crane main and auxiliary hoists are designed to perform typical plant maintenance and operational functions, and both hoists can be provided with a single failure proof or non-single failure proof design.

To facilitate multipurpose lifting, a maintenance jib crane is typically mounted on the main trolley, designed to provide lifting capability during maintenance operations of the entire polar crane. This reduces the need for cumbersome lifting equipment that is typically provided by the customer’s plant on a temporary basis to complete polar crane maintenance.

An additional feature of the multipurpose polar crane design is the containment dome inspection and maintenance station. This cleverly designed device utilizes a telescoping lifting device, which is installed on the multipurpose trolley to provide a safer, simplified and cost effective method for inspecting and maintaining the containment dome.

Nuclear polar crane features

FOR RELIABILITY

- Nuclear quality compliant

- Design based on over 50 years of operating experience

- Complete shop testing prior to shipment

FOR EASIER, LESS FREQUENT MAINTENANCE

- Direct access to maintenance points

- On-board diagnostics

- Telescoping maintenance platform

- On-board maintenance jib crane

- Forged steel wheels with precision bearing housing for longer wheel and rail lifetime

- Modular electrical enclosures designed for quick maintenance

FOR SAFETY AND ERGONOMICS

- Single failure design available

- Fail-safe operator controls

- Walkways and platforms to maintenance areas

FOR LOWEST LIFECYCLE COST

- Design based on total cost of ownership

- Fewer spares and less maintenance

- Weight optimization to reduce overall costs

FOR PERFORMANCE

- Infinitely variable speed control

- User-friendly operator controls

- Precise load positioning

- End carriages design for 360 degree circular movement