Lifecycle Care is our comprehensive and systematic approach to maintenance, supported by world-class tools and processes. In order to deliver Lifecycle Care in Real Time, we use the Industrial Internet, connecting data, machines and people. We bring together usage and maintenance data and combine it with our knowledge and experience, providing insights that allow our customers to optimize their maintenance operations and activities.

TRUCONNECT Remote Monitoring

TRUCONNECT Remote Monitoring uses sensors to collect data, such as running time, motor starts, work cycles and emergency stops, providing visibility to crane usage. It also provides brake and inverter monitoring. TRUCONNECT collects data through a condition monitoring unit installed on the asset. The data is transmitted to the Remote Data Center, where it is compiled and made available on yourKONECRANES.com.

TRUCONNECT data available on yourKONECRANES.com includes:

• Operating statistics, such as work cycles and running hours

• Alerts that provide designated personnel with notifications by email and/or text message of selected occurrences, including over-temperatures, attempted overloads and emergency stops, so that prompt action can be taken as appropriate.

• Estimates of remaining Design Working Period (DWP) of selected components, such as the hoist and hoist brake.

TRUCONNECT Remote Support

TRUCONNECT® Remote Support provides 24/7 access to a global network of crane experts and specialists, offering problem solving and troubleshooting to help reduce unplanned downtime. In controlled circumstances, two-way communication with the machines and their operators can be established in order to expedite corrective action. Remote Support is ideally suited for extremely remote locations. Remote Support requires TRUCONNECT Remote Monitoring and includes access to the experts at the Remote Support Center. It is available on rubber-tired gantry cranes and various engineered industrial cranes in selected regions.

yourKONECRANES.com

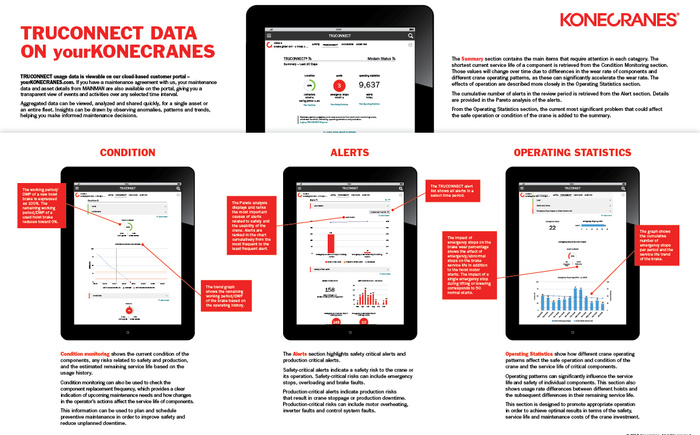

TRUCONNECT usage data is viewable on our cloud-based customer portal – yourKONECRANES.com. If you have a maintenance agreement with us, your maintenance data and asset details from MAINMAN are also available on the portal, giving you a transparent view of events and activities over any selected time interval. Aggregated data can be viewed, analyzed and shared quickly, for a single asset or an entire fleet. Insights can be drawn by observing anomalies, patterns and trends, helping users make informed maintenance decisions.