Konecranes sets the benchmark for pulp-and-paper industry lifting equipment. Our crane designers work closely with machine builders, pulp-and-paper makers and engineering companies to provide high-quality cranes and lifting systems specifically for the industry.

You are here

Goal-based engineering and proven results

Konecranes portal cranes combine unloading, transporting and decking of materials in one efficient operation.

Konecranes provides cranes and material handling systems for all lifting applications in the pulp-and-paper industry, such as process duty cranes, maintenance cranes, parent roll handling cranes and workshop cranes.

Every paper mill needs lifting equipment that performs lifting functions like raw material handling and machinery maintenance functions that support main processes.

Cranes needed for process equipment maintenance are typically wet end cranes, coater cranes, deinking plant cranes, vacuum pump maintenance cranes, mezzanine floor cranes and hoists, roll grinding workshop cranes, and workshop cranes.

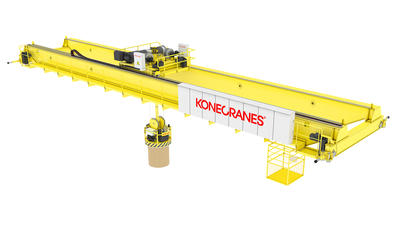

Konecranes dry end coater and winder cranes can handle all process machine output quickly, with the precision to transport heavy rolls safely around high-speed machines.

Mechanical and roll grinding workshops need lifting equipment for supporting functions. This equipment can include roll grinding machine cranes, parts storage cranes, workstation cranes, light cranes, and cranes for loading and unloading materials.

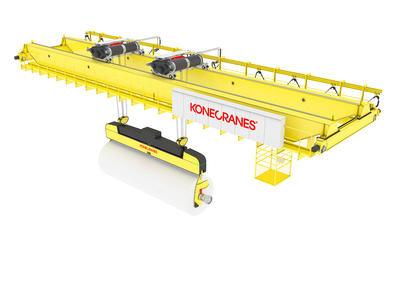

An automated vacuum lifter can optimize efficiency and accuracy of handling, transport and storage of paper rolls.

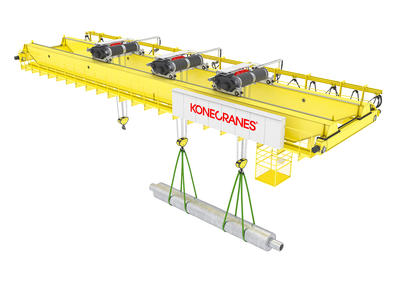

A slim mechanical gripper handles rolls gently with adjusted surface pressure and maximizes warehouse capacity through efficient use of space.

We offer a complete range of lift trucks, fork and carriage combinations, fork and shaft systems, paper bale clamps, paper roll clamps, and attachments based on a quick-change system.