The megatrend

Automation has been a growing megatrend in container terminals all over the world for over 20 years. However, automation is only part of the big picture and container terminals with manned cranes are still in the majority, and will remain so. Is automation the only way to improve yard productivity and safety? Not at all.

Idling is loss

In a typical container terminal with RTG or RMG yard cranes, the crane and the operator are in a one-to-one relationship. Each operator has a specific crane coupled to him at any given time. If the crane isn’t needed for a container handling task, then the operator is also idle – average idling time amounts to some 20% of the overall working time (a conservative estimate).

Improve efficiency and safety

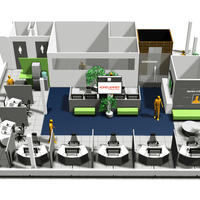

Konecranes offers the possibility of de-coupling the crane and operator. In this model, the operator works in a safe and ergonomic office environment and can operate different cranes at different times. The cranes are operated using Konecranes’ field-proven Remote Operation Station (ROS) concept. De-coupling the crane and operator, and eliminating operator idling time, can produce significant productivity increases -- many more container moves per day with the same equipment and improved employee safety and satisfaction. Watch the video below and contact us to discuss how your port could take this leap forward!