What happens during a Konecranes inspection?

Konecranes offers a variety of inspections to increase crane safety and reliability. But what exactly happens during an inspection?

Konecranes certified inspectors and trained technicians provide an accurate assessment of the condition of your equipment. They evaluate risks, identify improvement opportunities and provide recommendations.

An active preventive maintenance program is crucial to improving safety and productivity. Preventive maintenance can reduce downtime and increase reliability. We create a proactive customized maintenance plan based on your equipment, application and duty cycle.

Preventive Maintenance Inspections identify risks and improvement opportunities. Our vast experience and expertise allow us to tailor preventive maintenance to each manufacturer’s recommendations.

Routine Maintenance, such as adjusting and lubricating, is performed to keep your equipment running while satisfying manufacturer’s maintenance instructions.

Compliance Inspections are designed to satisfy regulatory requirements. Our trained inspectors and technicians are your go-to experts on local regulations. In some countries, regulations require the use of a third party.

In most countries, our MAINMAN™ Planned Maintenance product combines preventive maintenance inspections with routine maintenance and forms the foundation for our CARE Preventive Maintenance Program. Where permitted, we can also perform compliance inspections to satisfy local regulatory requirements.

In the United States and Canada, our MAINMAN™ Assessment product is a preventive maintenance inspection that is designed to give you an in-depth view of the condition of your equipment. MAINMAN Assessment forms the foundation of our CARE Preventive Maintenance Program and satisfies the requirements of the periodic compliance inspection. Routine maintenance is always recommended alongside a MAINMAN Assessment.

No matter which service product is being applied, our Risk and Recommendation Method drives our evaluation and consultative processes.

A component is inspected in order to ascertain its condition. Failures, deficiencies and violations are documented and categorized as either a safety risk, production risk or undetermined condition. In addition, a variety of improvement opportunities can be identified. Recommended actions are determined and discussed with you.

Only Konecranes provides expert advice every step of the way. As part of our consultative approach, we perform the following reviews.

Safety Review

This equipment-level review is to inform you of detected safety-related faults or issues before the technician leaves your site or before the equipment is returned to operation.

Visit Review

Following the completion of each service request, our inspector or technician will share the insights of their inspection or maintenance findings and review the identified risks and recommended actions.

Service Review

A service professional from your local branch will follow up with you to go through open recommendations and quotes, answer your questions and plan next steps.

Business Review

This business-level review of your current maintenance program is aimed at demonstrating a return on investment and driving continuous improvement.

Some components that are not readily accessible for inspection without disassembly may pose an undetermined risk. Konecranes uses advanced technology and non-destructive testing (NDT) to uncover latent or hidden defects.

Gear Case Inspection: Internal components are assessed using an endoscope and oil analysis. In some cases the gear case is disassembled to perform non-destructive testing on the internal components.

Hook Analysis: We use visual and NDT inspections combined with fatigue calculations of the hook/shank and critical components of the bottom block to evaluate hook life, condition and safety.

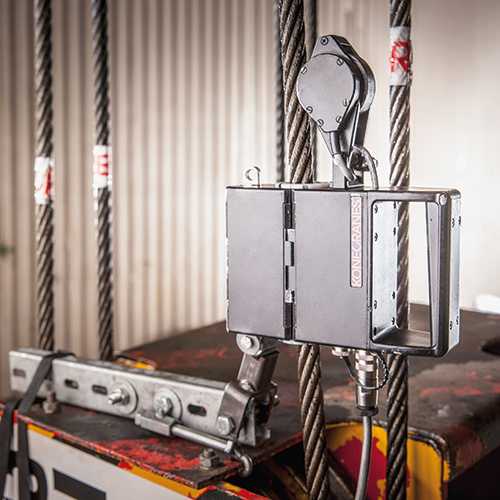

RopeQ Magnetic Rope Inspection: The internal wires, strands and core that are not readily visible are inspected with an electromagnetic device.

TRUCONNECT® Remote Monitoring provides you with data, such as running time, motor starts, work cycles and emergency stops, providing visibility to crane usage. The data is transmitted to the Remote Data Center, where it is compiled and made available on the yourKONECRANES.com customer portal.

It also notifies you of hoist overloads, emergency-stops and over-temperature occurrences through text or email alerts, allowing for prompt response.

Our customer portal, yourKONECRANES.com, gives you quick and easy access to your crane maintenance information. Usage data from TRUCONNECT and maintenance data and asset details from MAINMAN are linked, giving you a transparent view of events and activities over any selected time interval. Aggregated data can be viewed, analyzed and shared quickly, for a single asset or an entire fleet. Insights can be drawn by observing anomalies, patterns and trends, helping you make informed, fact-based, maintenance decisions.