RailQ™ Crane Runway Survey

Your rails may not be as straight as you think. A RailQ™ Runway Survey uses a remotely operated robot to give you an in-depth view of the alignment and condition of your crane rails. Measuring span, straightness, elevation and rail-to-rail elevation, RailQ gives you an easy-to-read report with 3D images that visualize the problem areas of your rails. Our engineers will review the data and provide recommendations. Combine RailQ with a CraneQ™ Geometric Survey for more information about the alignment of your crane’s wheels, guide rollers and other components.

CraneQ™ Crane Geometric Survey

Do your cranes suffer from premature wheel wear, rail wear, structural component failures or drive faults? All of these are common results of incorrect crane geometry. Have your crane operators complained about a crane making strange noises or positioning incorrectly? CraneQ Crane Geometric Survey helps you to find the root cause of these symptoms to avoid major problems and costly downtime.

RopeQ™ Magnetic Rope Inspection

Wire ropes can contain hundreds of individual wires. Broken strands on the rope exterior can be found by visual inspections, but the condition of the core and inner wire strands cannot be seen. RopeQ Magentic Rope Inspection combines visual and magnetic inspection methods to assess your rope exterior as well as the internal wires, strands and core that are not readily visible. The data can be used to assess whether the wire rope can continue to be safely used.

Crane reliability study

A Crane Reliability Study will assess the current condition of your crane and its remaining design life. A team of trained Konecranes specialists will gather information, perform a detailed inspection, provide customized calculations and perform an engineering analysis. The comprehensive report and expert consultation will give you a roadmap for equipment repairs, modernizations or replacement.

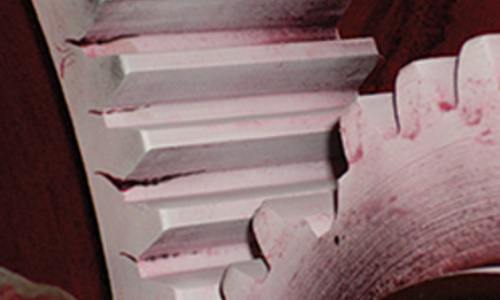

Gear Case Inspection

A Gear Case Inspection looks at internal components that are not typically evaluated during a routine inspection. We use an endoscope to visually inspect the gear wheels, bearings, shafts and keys, and perform an oil analysis. In some circumstances we recommend a gear case disassembly and non-destructive evaluation of the individual gears and other internal components.

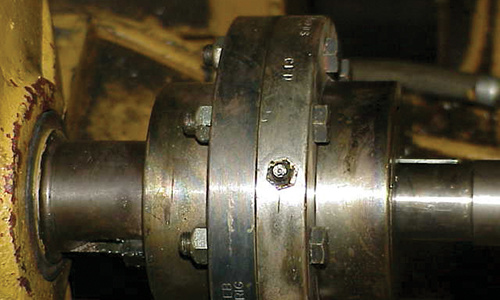

Coupling Inspection

The mechanical coupling between the hoist motor and the hoisting gear case is a critical component for the safe operation of lifting equipment. Failure of a hoist coupling may lead to load drop. The Coupling Inspection has been designed to uncover issues that may lead to coupling failure.

Hook/Shank Inspection

The Hook/Shank Inspection has been designed to uncover issues that may lead to hook or bottom block failure. The bottom block of a crane is made up of many internal critical components that are not typically evaluated during regular inspections and preventive maintenance.

Below-the-Hook Inspection

This inspection has been designed to inspect the removable devices attached to your crane hook during operation. The inspection identifies deficiencies and deviations from local regulations.

Design Life Analysis

The Konecranes Design Life Analysis calculates the remaining design life of the structures and machineries of your crane. A calculation of design life will give information that helps you assess your safe working limits and plan actions for continued equipment use.

Steel Structure Analysis

The steel structures of your crane shoulder the weight of your lifting operations. Those structures are subjected to fatigue as loads are lifted, and as fatigue life ends, safety can be compromised. The Konecranes Steel Structure Analysis can give you an accurate, detailed picture of the remaining fatigue life of the steel structure of your crane and help identify defects.

Rope Analysis

The Konecranes Rope Analysis is designed to provide expert consultation to answer your wire-rope- and rope-reeving questions. The analysis targets individual concerns such as rope selection, rope life, component failures, unexpected rope behavior, accident investigation or improvement opportunities, including recommendations on extending rope and component life.

Hook Analysis

The Konecranes Hook Analysis utilizes visual and NDT inspections combined with fatigue calculations of the hook/shank and critical components of the bottom block.

Crane Operator Training

Studies show human error is often the cause of crane accidents. Our crane operator training helps reduce errors and add skills that help avoid possible injury to personnel caused by improper operations. Training can be performed at your site or a Konecranes training facility.

VFD Capacitor Reforming

Variable Frequency Drives (VFDs) are sometimes stored for extended periods of time between uses. If a VFD goes unused for a year or longer, it must be reformed to recondition the DC-bus capacitors and restore its condition to prepare for operation under load. Konecranes VFD Capacitor Reforming is designed to reform your spare drives without ever removing them from your facility.

Compliance Gap Analysis

In the US and Canada, a Compliance Gap Analysis is a thorough study of your inspection methods and documentation, preventive maintenance program, repair processes and operator safety. Konecranes professionals tour your plant making notes and compiling information from discussions with designated crane operators and plant personnel. We provide a summary of any safety issues discovered that may need immediate attention as well as a final report for action plans.