Reduce the risk of load drop with Brake Monitoring

The hoist brake is one of the most critical wearing components in a crane. The brake is looked at during inspections, but with heavily-used cranes, the service lifetime of brake wearing parts may end sooner than expected. Additional inspections also require crane shutdown and provide only a snapshot of the current condition of the brake.

TRUCONNECT Brake Monitoring provides continuous information regarding the wearing friction material, air gap and different brake faults.

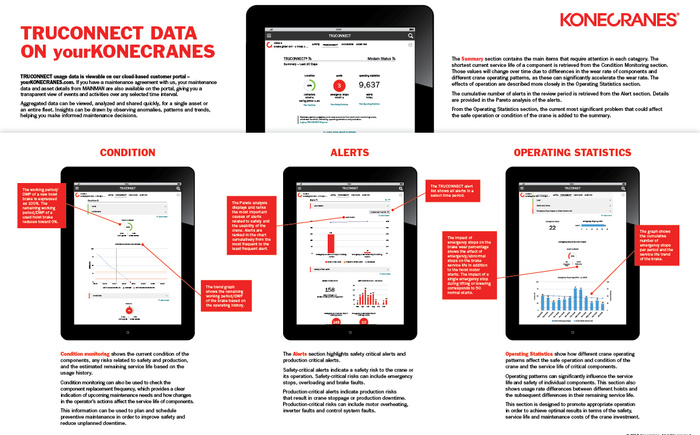

Your brake data, online – any time

The data, made available on the yourKONECRANES customer portal, can indicate brake maintenance needs in advance and shows if air gap adjustment is proper after installation. The data also provides a clear picture of brake overhaul intervals and replacement history, especially with unexpected brake problems. Brake fault alerts can be sent by text message or email, so maintenance planning can be done in advance.

A complement to Remote Monitoring

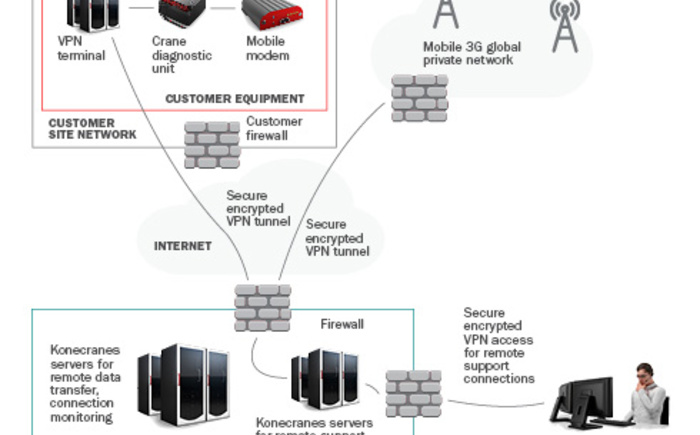

Brake Monitoring is an addition to TRUCONNECT Remote Monitoring – which uses sensors to collect data such as running time, motor starts, work cycles and emergency stops.

Brake Monitoring for new cranes or as a retrofit

The TRUCONNECT Brake Monitoring Unit is delivered with new Konecranes SMARTON and RTG cranes. Retrofits are also available for most Konecranes hoist models.

Benefits

- Continuous knowledge of brake condition

- Detects brake faults, reducing the risk of load drop

- Helps you avoid unnecessary brake disassembly for inspection

- Aids in maintenance planning by highlighting maintenance needs in advance, such as unexpected brake wear