Take a comprehensive look at the geometry of your overhead crane

Do your cranes suffer from premature wheel wear, rail wear, structural component failures or drive faults? All of these are common results of incorrect crane geometry. Have your crane operators complained about a crane making strange noises or positioning incorrectly? CraneQ Crane Geometric Survey helps you to find the root cause of these symptoms to avoid major problems and costly downtime.

With CraneQ, we verify the crane for squareness, meaning the end trucks must be parallel to each other and perpendicular to the bridge girder for the crane to track properly. In addition, the geometry of the end trucks themselves is verified, as is the alignment of the wheels within the end trucks. Finally, the girders for the crane are measured for camber.

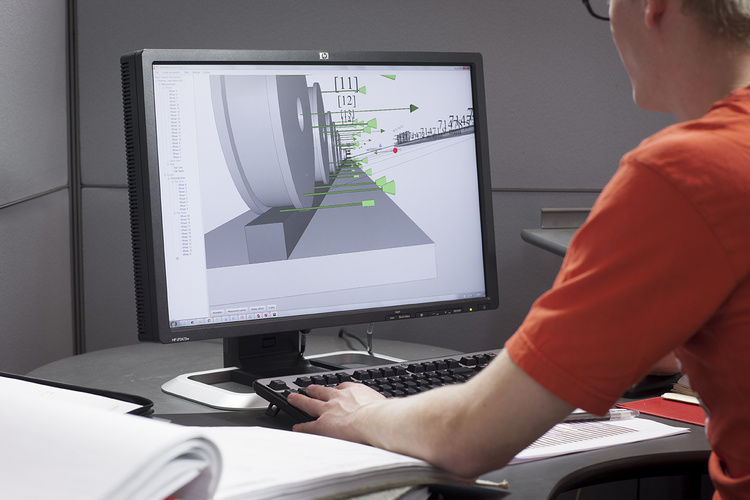

CraneQ is based on advanced and traditional measurement methods. Proprietary software and skilled survey technicians provide an extremely accurate geometric analysis of your crane. In addition to the survey results, we share our expertise to help you to plan corrective actions.

CraneQ delivers

- Accurate wheel and end truck alignment measurements

- Verification of the total square of the crane and its running components

- Analysis of crane girder camber

- Detailed accurate results with deeper analysis than available elsewhere

- Recommendations for aligning the wheels and to square the crane