Siemens Transformer (Wuhan) Co., Ltd. [herin after “Siemens Transformer Wuhan] is invested by Siemens (China) Co., Ltd., a wholly-owned subsidiary of Siemens Power Transmission and Distribution Group. The facility began production at the end of 2008, mainly specializing in the design and manufacturing of power transformers and reactors as well as the business of marketing development, sales and service.

Konecranes started the business cooperation with Siemens Transformer Wuhan by providing industrial cranes in 2009. In 2010, Konecranes began to implement maintenance services to Siemens and has been cooperating for almost seven years. Equipment maintenance service twice a year keeps the cranes in good working condition and helps the production lines run smoothly. It also helps significantly reduce downtime losses.

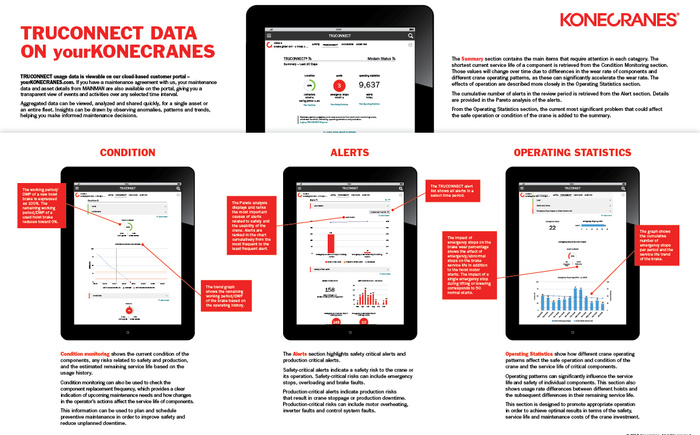

In January 2017, Konecranes launched a new service in China to help customers easily and quickly see their equipment and service information. By visiting yourKONECRANES.com, users can quickly view, analyze and share the information for a single asset or an entire fleet.

Siemens Transformer Wuhan needs a rigorous annual budget for equipment maintenance, including the status of each crane and estimated service spending. This work is cumbersome and time consuming as the number of assets grows annually. Konecranes unique customer portal yourKONECRANES.com supports business reviews to help users evaluate current and past service activities and associated costs, highlighting equipment risks and recommendations. The user can make an investment plan using the streamlined data.

The facility manager from Siemens Wuhan comments: “By using this system, it is much easier to review and plan annual equipment maintenance works, and the assets information, including the status, spending and maintenance records can be easily searched and reviewed in this portal, which is very related to our annual plan and budget we make. Meanwhile, there are improvement action plans and suggestions on the problems discovered. We are very satisfied with these conclusions and suggestions. Konecranes workflow has also been improved, the original inspection results were read through the paper reports. Now the technicians will inform us different risks and the harms to the cranes after inspection. The safety risks are informed separately and recommendations can be provided. All the inspection results and suggestions will be uploaded to the system, allowing us to access and view anywhere. These benefits ease our work.”

yourKONECRANES offers streamlined data access and real-time data updates that place a wealth of information in easy-to-read charts, including inspection and maintenance results, TRUCONNECT data and alerts, assets list and costs. The information is secured through real-time uploads by technicians. This helps provide users with a clear view of the assets and service activities. Konecranes provides Lifecycle Care in Real Time by connecting data, machines and people, and improving user productivity.